Related Solutions

Automated Battery Formation Solution

Quick Links

During the production of battery modules, a testing inspection station is often added near the semi-finished stage of processing to ensure the modules’ quality, function and safety. Since battery modules may have a potential hazard for short circuits, and manual testing introduces issues like inconsistent movement, handwritten data errors, long testing hours, possible issues in shipping traceability and more, many battery manufacturers are beginning to request automated testing systems. Automated testing can avoid human errors, increase product quality, and ensure personal safety, and will inevitably replace manual testing in the near future of battery production.

Reis Robotics is a leading technology company for robotics and system integration headquartered in Obernburg, Germany. The Reis Robotics group comprises 4 German subsidiaries and 16 international subsidiaries as well as representative agencies in many countries. Reis Robotics was founded in 1957 and after decades in development and realization of countless turnkey systems, they are currently the market leader for robotic automation systems. In addition to standard peripheral modules and advanced technical know-how, the company provides complete robotic solutions (including welding robots, foundry robots, handling robots, laser robots, and more) for automated production line use.

In order to enhance test automation and efficiency for the battery industry, Chroma has developed a lithium battery module automated test system to inspect packaging, welding and uniformity. Chroma also cooperated with Reis Robotics (Kunshan) to complete an automated battery module production and testing system that has been accredited and utilized by several battery manufacturers. This system applies to semi-finished battery modules, and performs automated testing for the synthesized measurements that generate PASS/FAIL test results. The application range includes battery modules for electric vehicles and energy storage systems.

Key features and specifications of the test solution:

- Pass/Fail validation for battery module production.

- Increases QA efficiency and reduces testing time.

- Inspection of BMS functions for voltage/temperature measurement accuracy as well as the distribution consistency of voltage/DC resistance/temperature for each serial cell of battery pack.

- Able to create the fixture to connect the customized battery module with an automated switch control.

- Charge/discharge power range: 2.5kW ~ 50kW

- Charge/discharge voltage/current range: 0V~200V/0A~2000A

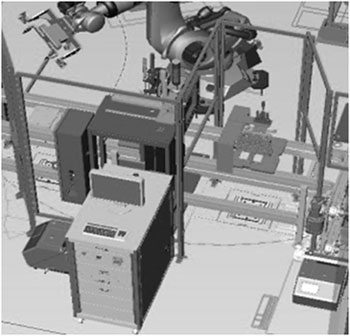

The figures below show the production line diagram and the automated inspection device.

|

|

| Production Line Diagram | Battery Pack Auto Test System |

With 30 years of experience in test and measurement instrumentation, Chroma is able to provide a wide variety of testing solutions for power and storage batteries. These include Regenerative Battery Pack Test Systems for battery cells, battery modules and battery packs, battery simulators and super capacitors. In addition, the solutions for BMS test systems, Semi-finished Battery Module Test Systems and Battery Pack EOL Test Systems have been adopted worldwide by manufacturers and third party laboratories. For any questions regarding automated inspection systems for battery modules, please provide your contact information and we will reach out to you for further service.

Home | Solutions | Support | Press Center | About Chroma | Contact

Copyright © Chroma ATE, Inc. All Rights Reserved.