Quick Links

|

|

Key Features

|

Chroma's 17020E is a high-precision system specifically designed for secondary battery module and pack testing. Highly accurate sources and measurements ensure that the test quality is suitable for performing repetitive and reliable tests crucial for battery modules/ packs, incoming and outgoing inspections, as well as performance, production, and qualification testing.

Three safety features are designed for battery testing: software for DUT communication protection, firmware for over voltage and over current protection, and multiple hardware protection circuits to ensure test procedures are performed safely.

The Chroma 17020E system is equipped with 2/4 independent channels to support dedicated charge/discharge tests on multiple battery modules/packs, each with discrete test characteristics to achieve a high utilization rate of the equipment.

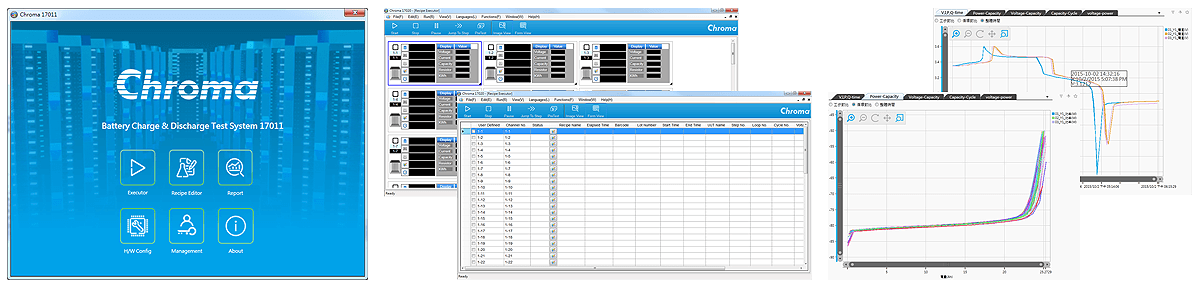

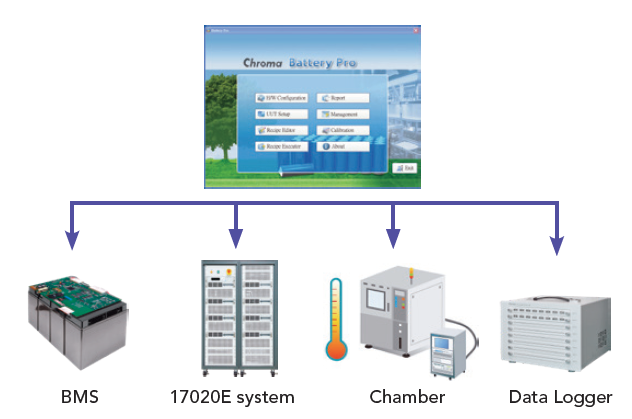

The Chroma 17020E system has flexible programming functions and may be operated with Chroma's powerful "Battery Pro"

software. The software can create cycling tests that range from basic charge or discharge to complex drive cycle testing for each channel or channel group. In the unlikely event of power or computer communication loss, the data is securely stored in the system's non-volatile memory, protecting against potential data loss and allowing for continuous flow after restart.

The Chroma 17020E, with its high precision output and measurement specifications, ensures consistent test quality. A seamless transition function between charge and discharge allows programming a dynamic driving curve that can simulate the actual use of the battery pack on an electric vehicle.

The Chroma 17020E has a regenerative energy feature that recycles the electrical energy sourced by a battery module during discharge either back into the channels in the system that are performing a charging test or to the utility mains.

- Able to load test, cut-off, and protection criteria to a charging/discharging device directly for execution to achieve multi-layer protection through internal software and hardware

- Able to integrate external hardware to get real-time monitoring parameters from BMS, Data Logger, Chamber, and I/O signals to execute warning/cut-off/power-off protection

- Able to monitor various voltage and temperature values of battery packs through readings from BMS and measurements on Data Logger; also able to perform instant judgment and protection based on set values

- Built-in multiple warning and protection modes: OVP, UVP, OTP, WIR_LOSS, CAL_ERR, POW_ERR, RM

- High frequency sampling measurement technology: Max. sampling rate

- Voltage accuracy : ± (0.02% of rdg. ± 0.02% of F.S.)

- Current accuracy : ± (0.05% rdg. ± 0.05% mg.)

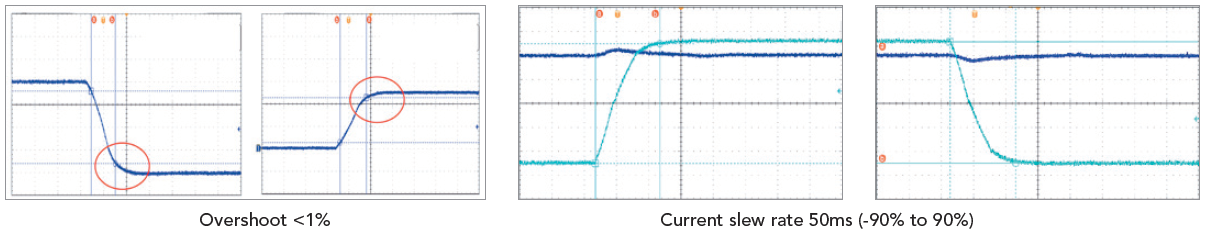

- Quick response test technology : 10ms(-90% to 90%) current slew rate applicable for various test applications

- Support dynamic driving profile simulation (waveform), which simulates the current and power state of real driving conditions to comply with the NEDC, FUDS and HPPC standards

High Frequency Sampling Measurement Technology

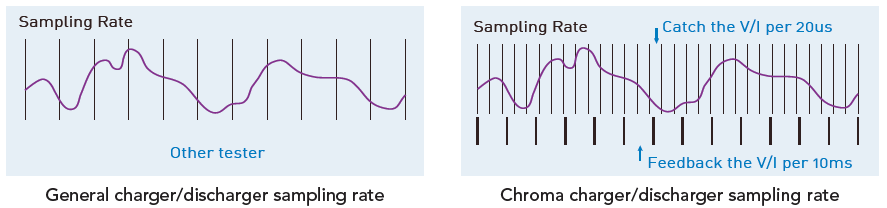

Generally, battery chargers/dischargers use software to read current values for power computing; however, limited data samplling speed colud result in large errors when calculating the dynamic current capacity. By increasing the V/I sampling rate and double integrating method, Chroma is able to provide capacity calculation with much higher accuracy. When the current changes, the data is not lost and the transmission speed is not affected.

- V/I sampling rate : 50kHz (per 20 μs)

- Integrate calculus : I for capacity ; V x I for energy

- Quick Response Test Technology

In quick response mode, the current is smooth without overshoot to avoid damaging the battery

- Current Ripple Noise <1%FS, Overshoot <1%

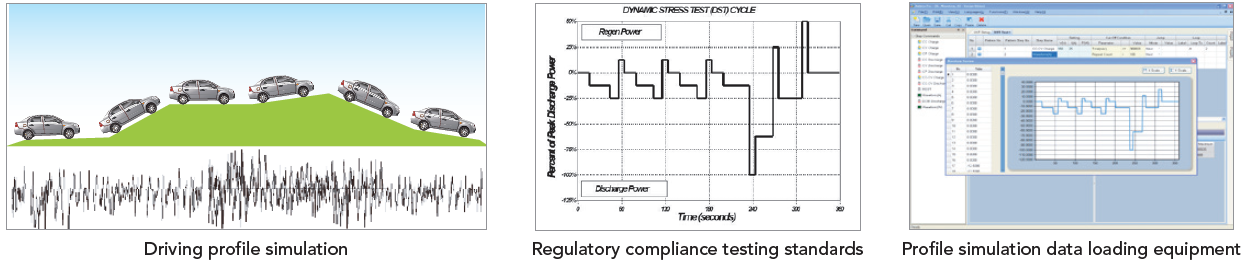

Dynamic Driving Profile Simulation

Battery packs are used under quick and irregular current conditions. The 17020E system simulates real conditions on the battery pack via the working condition simulator

- Dynamic charge/discharge power or current waveforms simulate the drive cycle or any real world application. In the dynamic current mode (waveform), the current transition time for maximum discharge and charge requires only 10ms

- Test steps can specify an Excel file from which to read the stored current/power waveform

- 720,000 points of driving profile memory available to save the waveform profile in each channel

- Interval for profile condition changes: 10ms~10sec

The 17020E test system is specifically designed to meet the diversified requirements for testing secondary battery packs with high safety and stability. Charge and discharge protection will abort tests when abnormal conditions are detected. Data loss, storage, and recovery are protected against power failure.

Real-time multi-channel battery pack status browse

Icon Manager: The test status of each channel is managed through different icons, easy to read and understand

Authority management: It sets the user's authority for operation

Fault record tracking: It records the abnormal state of each channel independently

- Thermal chamber: Synchronize temperature control with charge/discharge profile

- Data logger: Temperature or voltage data record that can be used for setting Cut-off and protection conditions

- BMS data record : Software setting to read data from BMS by data communication unit A692000/A692001. This supports SmBus and CAN bus. The data can be set in the conditions for cut-off or protection during testing

Home | Solutions | Support | Press Center | About Chroma | Contact

Copyright © Chroma ATE, Inc. All Rights Reserved.