Quick Links

|

Key Features

|

APPLICATIONS

|

|

|

OVERVIEW

The Chroma 52400 series is a hybrid compatible PXI based SMU (Source Measurement Unit) card which can be used in both PXI and PXIe chassis. It is designed for highly accurate source or load simulation with precision voltage and current measurements.

SMU combines four-quadrant-source with precision and high speed measurement. This unique capability makes a SMU the ideal instrument in many parametric test applications ranging from ICs, two-leaded components such as sensors, LEDs, laser diodes, transistors, to solar cells, batteries and many other electronic devices.

To meet various test requirements, the 52400 series has 16 control bandwidths allowing user selection of a stable operation, multi-ranges combined with 18 bit DAC/ADC to provide the best programming and measurement resolution and accuracy available at a sampling rate of up to 100k s/S. Special programmable output resistance allows users to set as internal series resistance of a battery making Chroma 52400 series SMU an ideal tool acting as a battery simulator.

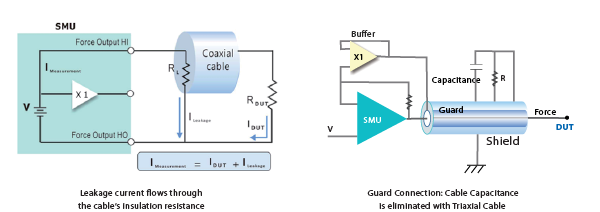

±force, ±sense and ±guards lines are standard to avoid leakage current and reduce settling time, especially for the mobile IC and Sensor test applications requiring very low current.

The 52400 series has a patented hardware sequence engine that uses deterministic timing to control each SMU. This sequencer comes with built-in 32k readings storage memory, allowing for cross module/card synchronization and latency free output control and measurement. This measurement is possible as no PC communication is required during a test process.

The C, C#, LabView, LabWindows APIs plus versatile soft front panels are offered as standard accessories. The back connectors are compatible with both PXI and PXIe chassis. All of these features enable easy integration to PXI or PXIe systems designed for any application.

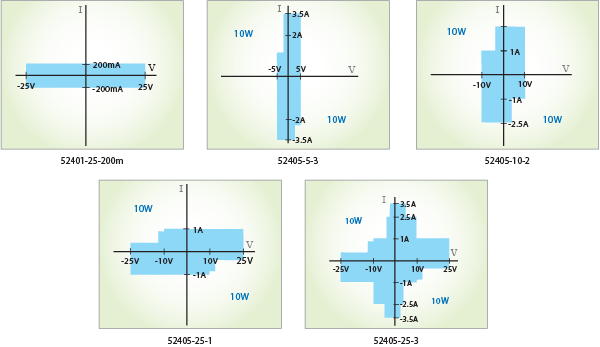

FOUR QUADRANT OPERATION

All Chroma 52400 series SMUs are designed for four quadrant operation for use by applications that require voltage/current source or load simulation. During a load operation, the module is limited by the PXI chassis' standard of 20W heat dissipation per slot. This limit is noted as the imbalance in the quadrant diagrams for higher power models.

The diagram below shows the quadrants of all Chroma 52400 SMU series.

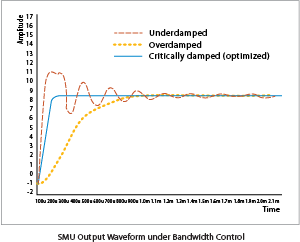

CONTROL BANDWIDTH SELECTION

To reduce test times, Chroma's SMUs are designed for fast response providing a high speed output voltage and current. The impedance of the DUT, the fixture and/or cabling may potentially cause the entire control loop instability under voltage or current output mode. An unstable loop may cause saturation, oscillation, or even damage the DUT. As a result, the user may be required to add a capacitor or an inductor on the test fixture to regain stability of the system.

To reduce test times, Chroma's SMUs are designed for fast response providing a high speed output voltage and current. The impedance of the DUT, the fixture and/or cabling may potentially cause the entire control loop instability under voltage or current output mode. An unstable loop may cause saturation, oscillation, or even damage the DUT. As a result, the user may be required to add a capacitor or an inductor on the test fixture to regain stability of the system.

The 52400 series SMUs provide 16 user selectable control bandwidths eliminating the need for additional physical capacitors or inductors strategically placed at the DUT. The Chroma Bandwidth selection can be part of the test parameters in a test script where the value can be adjusted to accommodate the DUT.

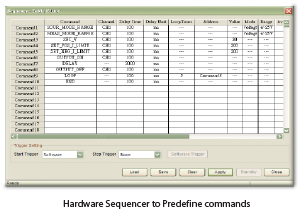

UNIQUE HARDWARE SEQUENCER

The Chroma Hardware Sequencer is a powerful tool that can predefine commands as instrument executable steps. This allows latency free control and measurement since no PC interaction is required during execution. The sequence optimizes the module's performance for applications like semiconductor test where speed and timing control

are critical.

The Chroma Hardware Sequencer is a powerful tool that can predefine commands as instrument executable steps. This allows latency free control and measurement since no PC interaction is required during execution. The sequence optimizes the module's performance for applications like semiconductor test where speed and timing control

are critical.

In this mode, once the instrument receives the start trigger, it will execute the commands in the sequencer table line by line or as defined upon trigger. Screen capture shown on the right is an example of a sequence profile setting by using Soft Front Panel provided by Chroma.

GUARDING FOR LOW CURRENT APPLICATION

Guarding is an important technique for very-low current measurements. Guarding reduces Leakage Current error and decreases Settling Time. It keeps the potential of the guard connector at the same potential as the force conductor, so current does not flow between the force and guard conductors. It also eliminates the cable capacitance between source measure unit (SMU) and DUT for faster and more accurate measurements.

MASTER/SLAVE OPERATION

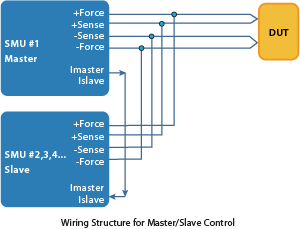

For maximum flexibility, Chroma 52400 series SMUs allow Master/Slave operation when higher current under FVMI mode is required. To ensure accurate current sharing between modules, and maximum performance, Chroma SMUs allow only similar models paralleled for higher current/

power.

For maximum flexibility, Chroma 52400 series SMUs allow Master/Slave operation when higher current under FVMI mode is required. To ensure accurate current sharing between modules, and maximum performance, Chroma SMUs allow only similar models paralleled for higher current/

power.

Current sharing is achieved by one channel operating as the Master under FVMI mode while the Slaves operate in FIMV mode. The Master channel is programmed in voltage mode while the Slaves are set to current mode. The Slaves will follow the Master's set voltage.

The figure to the right displays a blocked diagram for parallel configuration.

VERSATILE SOFT FRONT PANEL

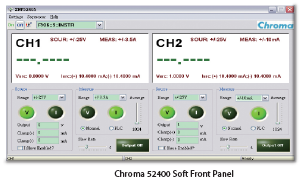

To integrate the 52400 series SMU systems, a versatile Soft Front

Panel is provided as a standard accessory which allows users to conduct verification test or debugging. This Soft Front Panel provides

GUI to set the SMU output mode, range and level. The measured

voltage or current reading will be shown after output is turned on.

For modules that have duel output channels, both channels can be

controlled by the same soft front panel.

To integrate the 52400 series SMU systems, a versatile Soft Front

Panel is provided as a standard accessory which allows users to conduct verification test or debugging. This Soft Front Panel provides

GUI to set the SMU output mode, range and level. The measured

voltage or current reading will be shown after output is turned on.

For modules that have duel output channels, both channels can be

controlled by the same soft front panel.

This Soft Front Panel also includes the control for hardware sequence setting described above. Users can save unlimited predefined profiles to the PC which can be recalled later for varying applications.

Home | Solutions | Support | Press Center | About Chroma | Contact

Copyright © Chroma ATE, Inc. All Rights Reserved.