Quick Links

Optoelectronic Test & Automation

|

Key Features

|

Laser diodes are becoming more ubiquitous. Current applications range from medical and defense, to being the critical backbone of the world's fiber optic communication networks. There are several highly precise processes involved in the production of Laser Diodes. These processes are all quite cost intensive ranging from wafer growth all the way to fibre alignment and package high speed testing.

The Chroma 58620 Laser Diode Characterization Station is a state-of-the-art full turnkey system designed specifically for Laser Diodes. Its features range from macro inspection of the facette or aperture active area to a full suite of electrooptical parametric tests. When Chroma's high capacity carrier is used, multiple devices can be rapidly repeatably indexed improving not only test times but the reliability of the tests themselves. The Chroma 58620 is equipped with a highly stable, large scale, temperature control platform to provide the ability to incorporate R&D style tests in a production environment. This enables the ability to study correlation between laser diode forward current and temperature.

Ultra-precise Carrier Design

Chroma's high precision carriers can be adapted to suit multiple form factors such as Chip on Carrier, Submounts, or Laser-Bar's. The innovative bi-lateral design is symmetrical with components placed on both sides to allow for a larger volume of components. The carrier is multi-layered to allow for components to be easily placed in their respective pockets yet secured once the other layers are mounted. The thermal interface structure allows for efficient component thermal contact along with a high degree of temperature control during heating and cooling cycles. At the touch of a button, an operator can perform full-scale automated testing once a carrier has been inserted.

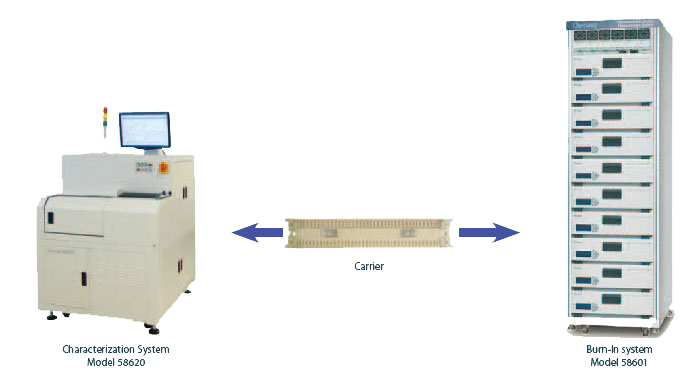

Sharing Carrier

One of the primary uses of high performance laser diodes are in the fields of optical data and telecommunications where the requirements for fiber coupling are quite stringent. If most DC parametric and optical characteristics are understood before a laser diode is inserted into the final product there is a greater cost savings and higher degree of in-field reliability. The Chroma 58620 is equipped with a fully automated alignment station to simulate a real-world fiber package coupling test to predict coupling efficiencies and spectral performance. Multiple optical heads and fibers may be used and coupled to an optical receiver such as an Optical Spectrum Analyzer (OSA) to analyze full spectral characteristics such as Side Mode Suppression Ration and Center Wavelength (λp, λc). Since every device is traceable with data, the Chroma 58620 affords the ability to correlate unpackaged optical performance with final package performance and helps in justifying a reduced final package test requirement.

Auto-aligment Fiber with AOI Assistance

From developed technology in Semiconductor IC test technology, Chroma 58620 introduces batch processing through the sharing carrier and changing kit to the Laser Diode industry. The carrier protects the laser diode from being handled and damaged as it is processed as test lots through the burn-in and test process while providing the hooks for data tracking thus increasing both productivity and yields. This same carrier is designed to operate with the Chroma 58601 OptoElectronic SMU Module for seamless burn-in & test processing. Through a 58620 change kit, as the laser diode under test changes (by evolving design or new product), the systems can adapt to various form factors and features. This flexibility allows for one solution to potentially test TO-Can, Chip on Carrier, Laser-bar, etc.

High Precision Control Platform

External and Internally induced thermal stresses on Laser Diodes strongly influence spectral and other electro-optical characteristics. Due to these issues, the Chroma 58620 includes a temperature control platform using a high precision Chroma 54130 - 300W TEC Controller and a Chroma 51101 Data Logger. These are highly regarded as world class instruments to ensure the uniformity of the carrier temperature and hence the devices under test. There are several thermal sensors placed along the carrier platform to ensure both a high degree of temperature uniformity and stability.

Home | Solutions | Support | Press Center | About Chroma | Contact

Copyright © Chroma ATE, Inc. All Rights Reserved.